Aucto Asset Catalog

AI powered technical specifications and market values on industrial equipment, machinery and parts.

OKUMA MILLAC 852VII VERTICAL MACHINING CENTER

Original Equipment Manufacturer: OKUMA

Model: MILLAC 852VII

Want this asset? Get notified when in stock

Asset Valuation

Based on Asset Condition:

Technical Description

Technical Specifications

Data may contain nonconformities, defects, errors, or omissions and should be verified before use. All data that Aucto provides is "as is" without any guarantees of any kind. If you see data that looks to be incorrect or needs to be updated, please let us know by emailing us at support@aucto.com with the product name, page URL, the incorrect data and updated values (if available). We will try our best to update inaccurate data as quickly as possible.

Attributes

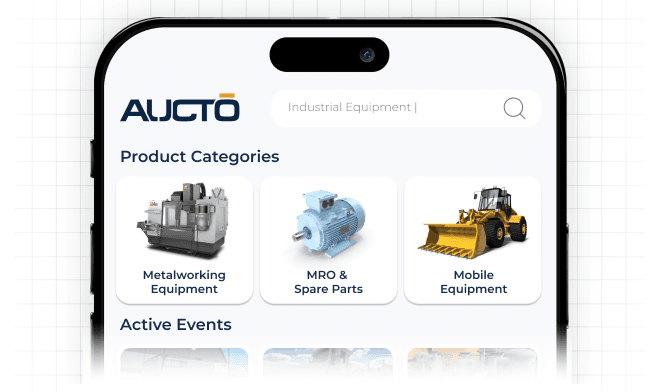

Buy and Sell vertical machining centers on the Aucto Marketplace.

Access the top pre-owned and used heavy equipment on the Aucto Marketplace. Browse our massive selection of loaders, bulldozers, excavators, fleet vehicles and more. Find the equipment you need at only a fraction of the price on Aucto.

Similar Catalog Assets

Year

-

Year

-